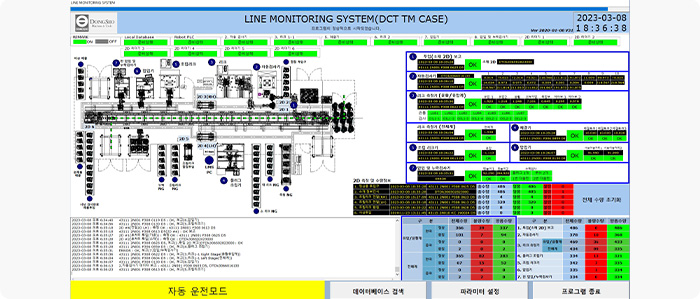

Processing and Assembly Monitoring Control System

LMS(Line Monitoring System): System in charge of interface for data collection and remote controlling

Product tracking management through Log saving period and location setting features → Improving defect cause confirmation and non-adjusted ratio

Saves production data by process and provides convenience of management through remote monitoring features