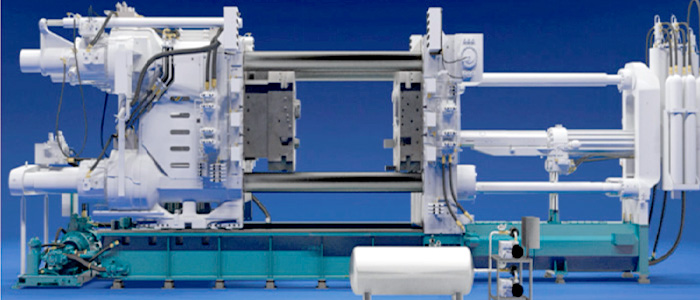

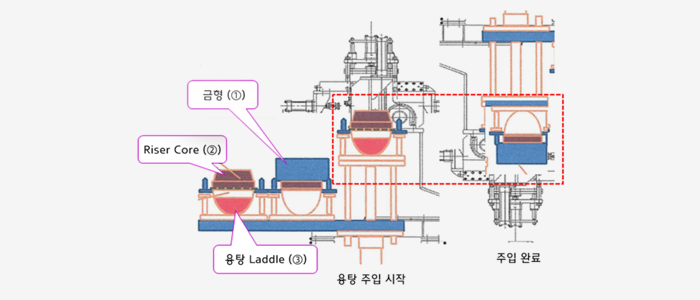

High Pressure Die-Cast : HPDC

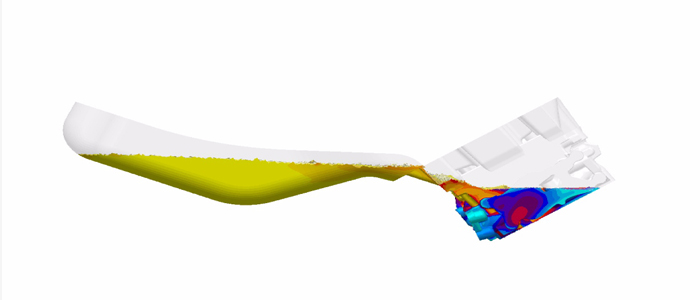

Technology of inserting flow into the mold at high pressure and speed, allowing fast production of detailed products, high productivity, thin products with elegant casting surfaces.

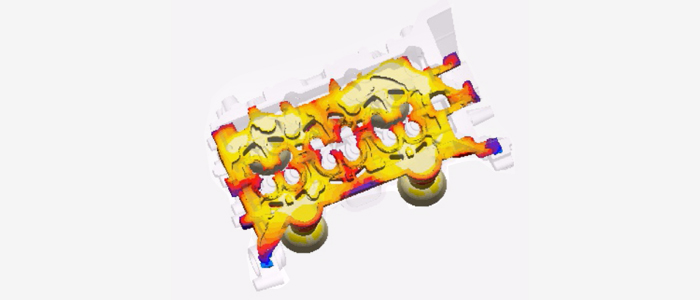

- Realization of engine lightening, high fuel effieciency

- Complex forms and thin casting products can be produced

- Mass production available ccompared to other casting methods